There are various companies who tend to be industry leaders in fibre glass sleeve and electrical insulation. Fibreglass electrical insulation sleeving is formulated to cope up with the diverse needs of the clients.

The benefits and features of fibre glass

Fibre glass as the name suggests is a viable, easy and an affordable alternative to a heat shrunk tube. They are formulated in such a way so as to fit comfortably over cable or wire without the need for an initial shrinking to size via the use of heat. In fact, they end up providing a wide range of benefits that includes the ability to be heavy weight braided and resin- saturated. What it means is that it is not going to burn, melt or tend to become brittle. Being abrasion resistant and cut through it can be easily cut with scissors and this ensures it is easy to install.

There is bound to be minimum amount of dusting when fibre glass sleeve is cut or handled, even it can easily resist engine chemicals and gasoline. It is resistant to higher temperatures and this is the reason why it is being used as a thermal protection for items like cables, wires or hoses which would be subject to harsh conditions. Typically, it is found in exhaust systems and engine manifolds.

It is durable and tough, acrylic coated fibreglass sleeving, even under conditions of abrasion, extreme vibration, temperature variations and mechanical stress is able to maintain its structure. Hence it is part of various applications that would retain or reflect heat in conditions where temperature reaches alarming trends.

The customization options associated with fibreglass sleeving

Fibreglass sleeving is bound to provide numerous customization options. It could be applied in the form of a heat-treated glass, a modified version of acrylic coated glass and heat treated along with saturated fibre glass.

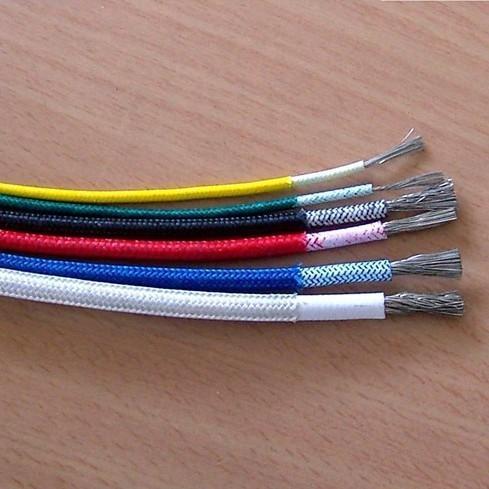

The fibre glass sleeving is available in muted colours, It is available in the form of white, black, clear and natural with a tan hue. Normally it is braided, knitted and has undergone a major heat transformation procedure. The diameters are of various sizes that can cope up with the demands of the clients. As the material tends to be spoofed, it is seen that requests for any type of length are something that can be taken care off.

Most of the reputed companies are known to handle top production volumes irrespective of the fact whether the client requires a single prototype. Blanket orders or high-volume ones. Coming to the lead times it is dependent on specific request. Though the quotation is something that is on a job-by-job basis, as even rush or emergency services are available.

Fibreglass sleeving is something that is available for a wide range of industries. Some of the industries where it is found are retail stores, hospitals, iron and steel etc. Their use is paramount and of late and their importance is going to increase on a daily basis.