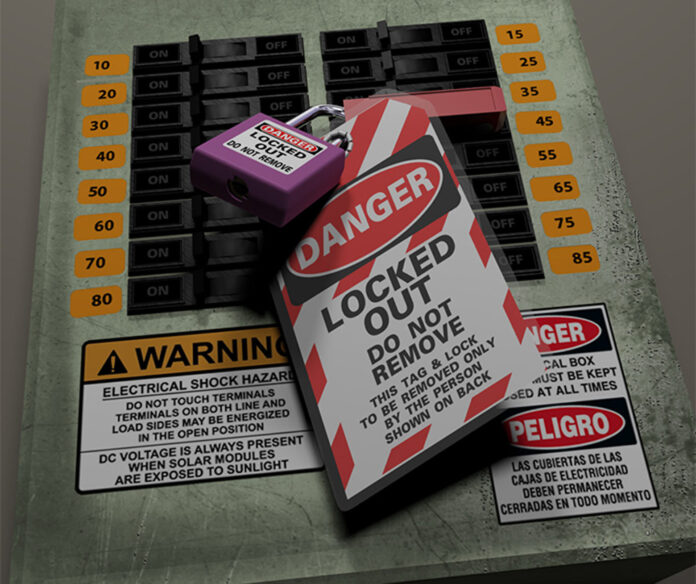

OSHA’s basic sector control of harmful power (likewise called lockout/tagout or lockout/block out) requires that an employer develop an lockout tagout training canada to ensure that employees isolate makers from power resources (including mechanical, electric, hydraulic, pneumatic, chemical, as well as thermal power) as well as make those machines inoperative prior to any kind of employee services or keeps them-where servicing and preserve consists of building, mounting, setting up, changing, lubricating, cleaning, unjamming or making adjustments or device modifications where workers may be subjected to the energizing or start-up of the equipment.

Various other sectors

There specify industries that either are merely not covered or have their own requirements on Propane Handling Training:

- While there are other OSHA criteria that look for electric shock and melt threat, the basic requirement does not put on electric dangers from service, near, or with conductors or equipment in electric usage (facility electrical wiring) installments, which are described by Subpart S of 29 CFR Component 1910.

- Managing dangerous power in installations for the unique purpose of power generation, transmission, as well as circulation, including relevant tools for communication or metering (these types of installments are covered by 29 CFR1910.269).

- Farming, building, as well as maritime sectors or oil and gas well drilling and also servicing are not covered by the OSHA basic criterion on lockout/tagout.

General sector exceptions

Where the general industry criteria apply, there specify situations where lockout/tagout is not called for. These include:

- Solution and also upkeep activities where exposure to hazardous power is controlled completely by disconnecting the tools from an electrical outlet and where the staff member doing the solution or maintenance has exclusive control of the plug. It must be noted that this applies just if electricity is the only kind of hazardous power to which the employee might be subjected. A lot of mobile hand devices and also a considerable number of cable- and plug-connected equipment and also tools fall under this category-however, with the cable- as well as plug-connected equipment, it is essential to make sure that the ONLY type of dangerous energy is electrical.

- When hot faucet procedures are done on pressurized pipes that distribute products such as gas, heavy steam, water, or oil items AND the company shows that service continuity is vital, shutdown of the system is unwise, and also the company has recorded treatments that the employee adheres to as well as special equipment that the employee utilizes that gives proven and also reliable staff member security.

- Maintenance operations that need to be carried out with the power on, such as making great changes like centering the belt on conveyors or repairing where recognizing the resource of the problem as well as inspecting to make sure that it has been remedied calls for that the tools or equipment be invigorated. In these circumstances, OSHA calls for the company to supply reliable protection when employees must carry out such operations. (Nevertheless, various other servicing and also upkeep actions on the exact same machinery or equipment which does not need that the devices be stimulated would certainly need lockout/tagout procedures be carried out.).