Microchannel coils have emerged as a game-changing solution in the world of heat exchange systems, particularly in HVAC (Heating, Ventilation, and Air Conditioning) applications. Their unique design promotes enhanced thermal efficiency and reduced refrigerant charges, which is becoming increasingly critical in light of environmental regulations and sustainability goals.

The Evolution of Microchannel Technology

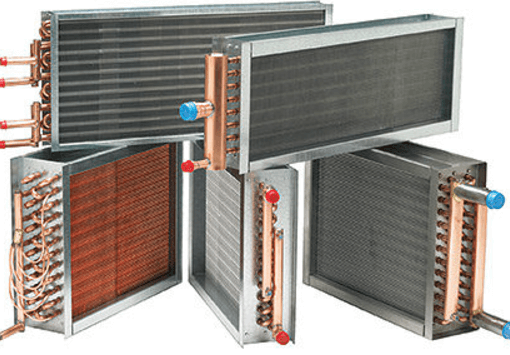

Initially developed for the automotive industry, the microchannel technology has found applications across various sectors. Microchannel coils are characterized by their flat, non-circular tubes and small, closely spaced channels that allow for a larger surface area, significantly improving heat transfer rates. This innovation has led to a reduction in the amount of refrigerant required, making systems more eco-friendly.

The adaptation of this technology into commercial and residential buildings signifies a substantial shift towards more energy-efficient systems. Facilities that have adopted microchannel coils report not only lower energy bills but also improved overall system performance.

See also: Technological Solutions to Combat Detention Times

Key Advantages of Microchannel Coils

- Compact Design: Microchannel technology allows for smaller heat exchangers without sacrificing efficiency. This compactness is essential for applications where space is a premium.

- Higher Efficiency: The increased surface area in microchannel coils enhances heat transfer, leading to improved system efficiency. This is particularly advantageous in variable load applications, where performance can fluctuate significantly.

- Reduced Refrigerant Charge: Traditional heat exchangers often require significant amounts of refrigerant, which can be harmful to the environment. Microchannel coils dramatically reduce this requirement, aligning with global initiatives to minimize greenhouse gas emissions.

- Enhanced Durability: The robust construction of microchannel coils, often made from materials like aluminum, helps resist corrosion and prolongs service life, resulting in lower maintenance and replacement costs.

Applications Across Industries

Microchannel coils are not limited to HVAC systems; they have found vital uses in refrigeration, automotive, and even industrial processes. For instance, in refrigeration applications, these coils are utilized in walk-in coolers and freezers, significantly improving energy efficiency while maintaining desired temperature levels.

In automotive applications, microchannel heat exchangers have been successfully implemented in radiators and condensers, reducing weight and enhancing performance. The ongoing development in this area highlights the versatility of microchannel technology.

Future Trends in Microchannel Coil Development

The future of microchannel coil technology is promising, with continuous research focused on further enhancing performance. Innovations such as smart sensors and AI-driven control systems are being integrated with microchannel designs to optimize operation based on real-time data.

Moreover, as industries move towards more sustainable practices, the demand for alternatives like natural refrigerants compatible with microchannel technology is increasing. This shift opens up new avenues for innovation, ensuring that microchannel coils remain at the forefront of heat exchange advancements.

In the realm of HVAC, microchannel coil technology is increasingly incorporated into new system designs, reflecting a growing recognition of its ability to meet modern efficiency and environmental standards.

The Path Forward

The trajectory of microchannel coil technology underscores its vital role in shaping the future of heat exchange systems. As industries aim for higher energy efficiency and lower environmental impacts, the innovations in microchannel designs are set to pave the way for smarter, more effective solutions. The promise of improved heat transfer, reduced refrigerant use, and enhanced system longevity places microchannel technology at the center of a transformative movement in energy efficiency.